磁悬浮离心鼓风机是将磁悬浮轴承技术和高速电机技术融入传统风机之中所形成的一种高效的节能环保的新型风机,具有机构简单、高效智能、一体化、操作维护简单、运行费用低的显著优点,可广泛应用于污水处理(市政、工业及其他)、物料输送、食品医药、纺织印染、皮革造纸、脱硫脱硝等项目中,节能效果显著。

磁悬浮离心鼓风机是将磁悬浮轴承技术和高速电机技术融入传统风机之中所形成的一种高效的节能环保的新型风机,具有机构简单、高效智能、一体化、操作维护简单、运行费用低的显著优点,可广泛应用于污水处理(市政、工业及其他)、物料输送、食品医药、纺织印染、皮革造纸、脱硫脱硝等项目中,节能效果显著。

磁悬浮离心鼓风机是将磁悬浮轴承技术和高速电机技术融入传统风机之中所形成的一种高效的节能环保的新型风机,具有机构简单、高效智能、一体化、操作维护简单、运行费用低的显著优点,可广泛应用于污水处理(市政、工业及其他)、物料输送、食品医药、纺织印染、皮革造纸、脱硫脱硝等项目中,节能效果显著。

高效率:

采用自主设计的高效离心叶轮+高效同步永磁电机驱动

低振动,低噪音:

由于采用先进的磁悬浮轴承系统,转动部件与机械系统无接触,无机械摩擦,运转稳定,振动很小,整机噪音很低。

无润滑油,无机械保养:

由于采用先进的磁悬浮轴承技术,省却了传统风机所必需的复杂的齿轮变速箱及油性轴承,所以做到了无润滑油、无机械保养。

有效地降低了用户的维护成本,提高了曝气系统及整个污水处理厂运行的稳定性。

易安装:

磁悬浮离心式鼓风机重量轻、体积小,无需大型起吊设备,两名技术人员即可轻松完成安装工作。

易维护:

日常维护仅需要更换空气过滤布,方便简单。

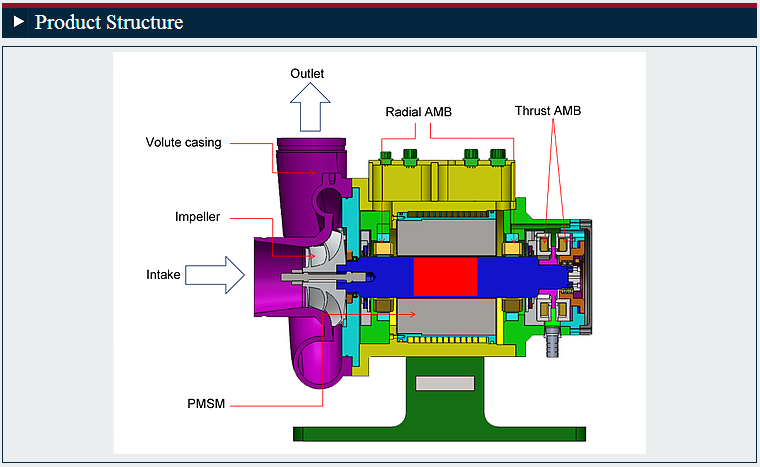

Turbo Blower is used to compress air by centrifugal movement of the rotor, then transport the compressed air to the desired place.

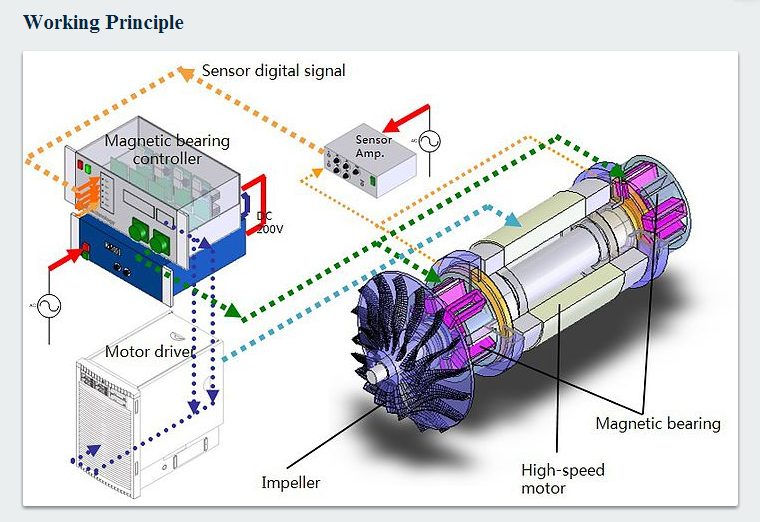

AMB Turbo Blower uses active magnetic bearing and high-speed permanent magnet synchronous motors(PMSM)technology, which is a new type of energy-saving and environmentally friendly product through integrated design.

Environmental protection

- With calculation of the AMB turbo blower with capacity of 100kW, equal to reduction of emission of 275 tons carbon dioxide.

- The AMB turbo blower requires no lubrication and the airs it transmitted are clean and free of pollution.

- The AMB turbo blower produces little noises and will not impact the surrounding office and living environment.

Adoption of advanced technology

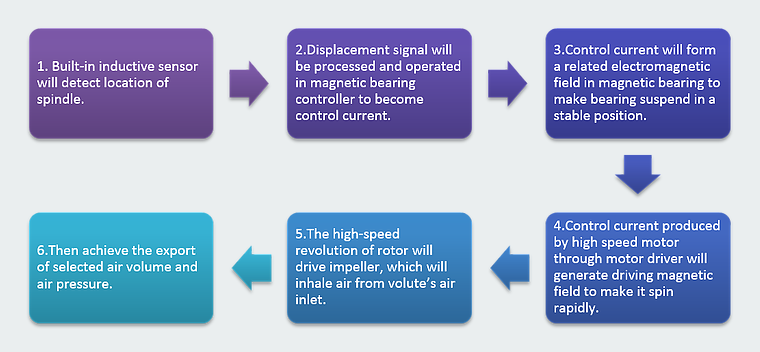

- The active magnetic bearing system is adopted without abrasion and in no need of lubrication of maintenance.

- High-performance frequency converter is adopted to control the revolving speed and multiple control modes are available for choice.

- The advanced control system is adopted to monitor the operating status and is able to conduct remote control and there is no need to designate personnel for guarding.

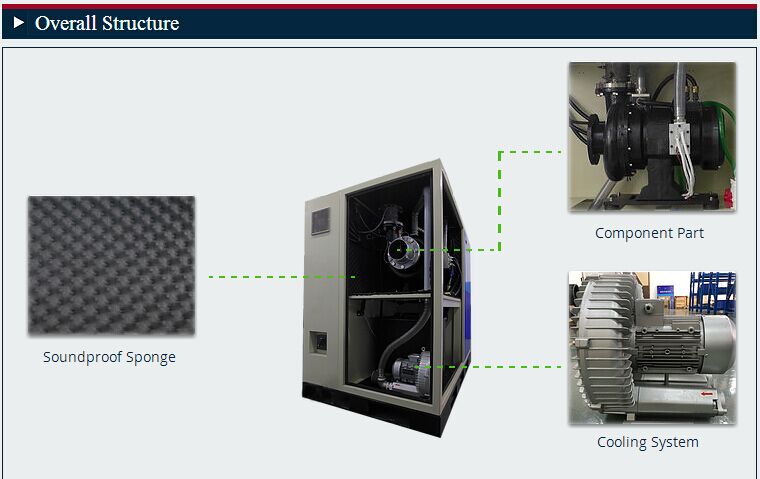

- Fully enclosed water cooling system and air cooling system are employed for heat dissipation of blower so as to guarantee the air blower stays at a stable and highly efficient operating status.

- The modular design makes the maintenance convenient and fast.

low operating cost

- The magnetic bearing is completely free of friction such that the possibility of product damage can be reduced and the service life of blower can exceed 20 years.

- The maintenance of AMB turbo blower is easy and only routine replacement of filter is required.

- The maintenance of AMB turbo blower requires no lubrication system to save the cost for lubricant oil and clearance.

- The motor adopts directly connected drive which is small and light to save space occupation.

- Low manufacturing costs and maintenance costs, timely after-sale service.